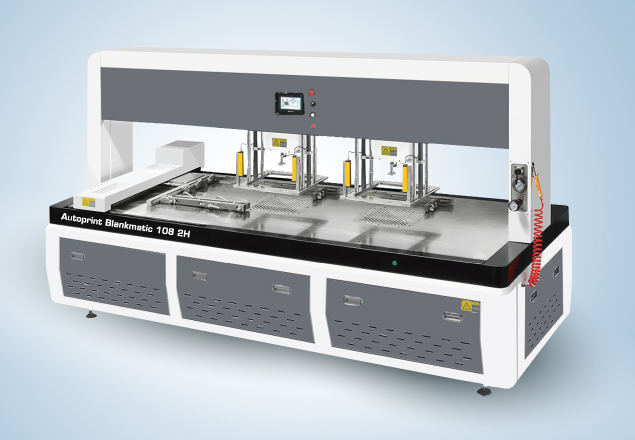

BLANKMATIC 108 2H - AUTOMATIC OFFLINE BLANKING MACHINE

Stripping & Blanking Machines strip cartons from die-cut sheet at extremely high speeds. Various types of die- cut sheets like Lock Bottom, Single Cut & Double Cut can be stripped using this machine.

BLANKMATIC 106 2HWR - AUTOMATIC OFFLINE BLANKING MACHINE

Autoprint is committed to bring modern cutting edge technology to its customers.A result of this commitment is Autoprint Blankmatic 106 -2HWR.