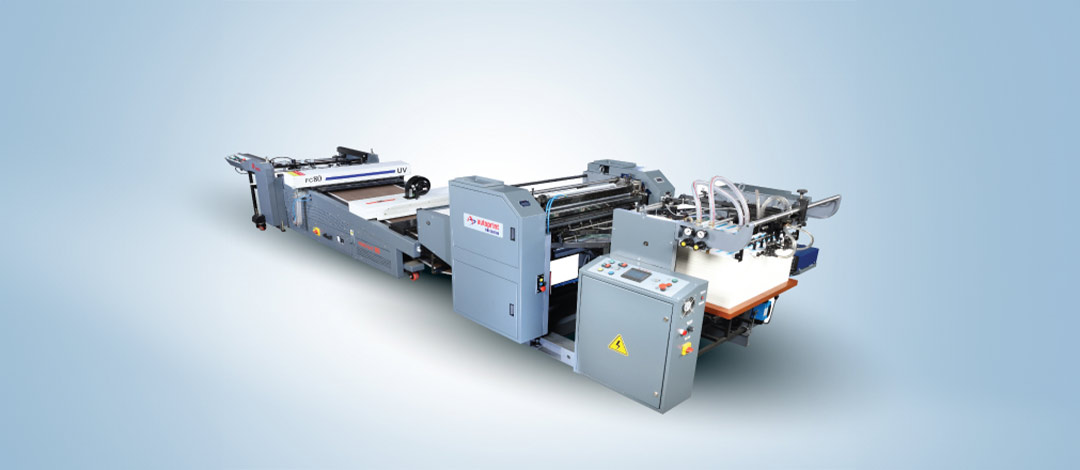

In the world of printing and embellishment, UV Coating Machines play a crucial role in enhancing the aesthetic appeal and durability of various products. We, a leading UV Coating Machine Manufacturer, provide expert tips on operating and maintaining them.

Operating Tips for Automatic UV Coating Machines

- Optimize settings: Adjust UV Intensity, speed, and coating thickness for optimal results.

- Choose the right coatings: Select compatible UV Coatings for your machine, including Spot UV, Aqueous, and Drip-off Coatings.

- Monitor temperature: Maintain the recommended temperature range for efficient UV Curing.

Maintenance Tips for UV Coating Machines

- Regular cleaning: Clean the machine, UV Lamps, and coating system regularly to prevent contamination.

- Lamp replacement: Replace UV Lamps as recommended by the manufacturer to ensure consistent UV Curing.

- Coating system maintenance: Clean and replace coating nozzles, pumps, and filters to prevent clogging.

Additional Tips for Embellishment and UV Coating

- Train operators: Ensure operators are trained and familiar with the machine to minimize errors

- Follow safety guidelines: Adhere to safety protocols when operating the machine to prevent accidents.

- Keep records: Maintain a maintenance log and track machine performance for optimal efficiency.

UV Coating Machine Options*

We offer a range of UV Coating Machines, including:

- Automatic UV Coating Machines

- Spot UV Coating Machines

- Aqueous Coating Machines

- Drip-off UV Coating Machines

- Digital Spot UV Coaters

- Offline Aqueous Coaters

Invest in Quality UV Coating Equipment

When it comes to UV Coating and Curing Machines , invest in quality equipment that meets your specific needs. Contact us to learn more about our UV Coating Machine Prices and find the perfect machine for your business.