AUTOPRINT HOT FOIL UNIT

Hot foil stamping is a finishing method used to give texts and patterns an eye-catching appearance. The Hot foil can have a glossy or matte finish with a colored, metallic or holographic appearance. The Size of the area that can be covered varies from very small details such as logos, captions, key lines, and pictures that can be Hot foiled as per design. Hot foil enhances visual appeal and adds more value to every print job. Autoprint introduces a Hot foil facility as an optional feature with Dextra - 80 Die - Punching Machine.

Retrofitable Hot foil stamping Attachment

Dextra 80 can be converted for foil stamping application at the site with a hot foil attachment.

Quick Changeover between Die Punching and Hot foil stamping

Additional Chase Bracket fitted with the heater plate is Provided for Hot stamping. The operator can easily replace the die-punching chase bracket with the hot foil chase bracket and the foil stamping job can be started quickly. Similarly, after completing Hot foil stamping jobs, the operator can immediately start the die punching operation by changing the die chase. This is possible as the heater is fitted on the chase bracket and there is no need for the machine to cool down.

Power saving Heater Plate

Heater Plate has 3 heating zones which can be optimized depending on the sheet size and controlled with a separate panel box. These heaters have an independent thermostat which is used to set and reach the correct temperature very quickly.

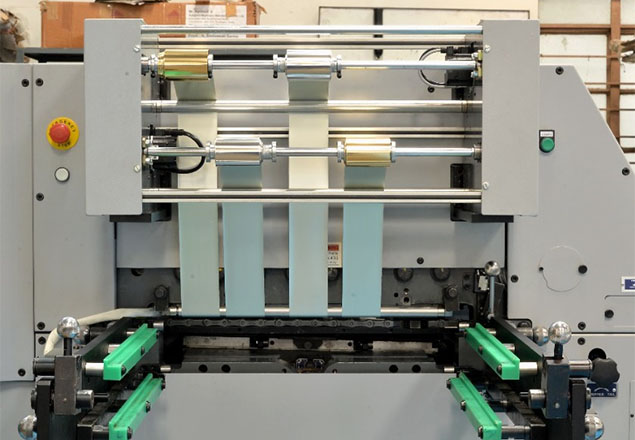

Foil feeding system

Servo-controlled foil feeding is running perpendicular to the direction of the paper feeding direction. Hot foil attachment is driven by 2 independent servo motors for pulling the correct length of foil with foil saver settings on the rewind section. Two different shafts are provided for foils, both on the upwind side and rewind side. Hence different pull lengths can be used simultaneously using the independent servo motors. Multiple foils of large diameter can be fixed on each shaft to reduce foil consumption. Another 2 servo motors are used to control the unwind section. Hot foil attachment is also provided with sensors to indicate the completion of the foil roll and thereby reducing wastage.

View BrochureHot Foil Stamping

Hot foil stamping is a printing technique that involves the transfer of metallic or colored foil onto a surface using heat and pressure. The foil is often made of a thin, flexible material like aluminum, and is available in a range of colors and finishes, including metallic, holographic, and matte.In the printing industry, hot foil stamping is typically used for creating high-end and luxury packaging, labels, and other printed materials that require a premium finish. It is often used in combination with other printing techniques like embossing, debossing, and letterpress to create intricate and textured designs.

Hot foil stamping involves the use of a heated die or plate, which is used to transfer the foil onto the surface of the material. The die is typically made of metal and is etched with the design or pattern that is to be stamped onto the material.

The foil is placed onto the material, and the die is pressed onto the foil with heat and pressure, causing the foil to adhere to the surface of the material. The excess foil is then removed, leaving behind the stamped design.Hot foil stamping can be used on a variety of materials, including paper, cardboard, leather, plastic, and textiles, among others. It is a popular choice for high-end packaging and printed materials, as it can add a level of sophistication and elegance to the finished product.

Hot foil stamping can be used on a variety of materials, including paper, cardboard, leather, plastic, and textiles, among others. It is a popular choice for high-end packaging and printed materials, as it can add a level of sophistication and elegance to the finished product.

Hot Foil Stamping Machine Uses

A hot foil stamping machine is a printing machine that uses heat and pressure to apply metallic or colored foil onto a surface. The machine uses a heated plate or dies, typically made of metal, to transfer the foil onto the surface of the material.Hot foil stamping machines are commonly used for embellishing and adding a decorative touch to various materials, including paper, cardboard, leather, plastic, and textiles. The foil can be applied to create a variety of designs, patterns, and even text, giving the finished product an elegant and high-quality appearance.

In the printing industry, hot foil stamping machines are often used for producing high-end and luxury packaging, such as wine bottle labels, cosmetics packaging, and high-end consumer products. They are also used in the production of business cards, invitations, and other printed materials where a premium finish is desired.

Hot foil stamping machines are available in various sizes and configurations, from small tabletop models to large industrial machines capable of producing high volumes of finished products. They can also be used in combination with other printing techniques, such as letterpress and embossing, to create unique and intricate designs.

Steps Involved in the Hot Foil Stamping

Hot foil stamping is a printing technique that involves transferring a metallic or colored foil onto a surface using heat and pressure. Here are the basic steps involved in hot foil stamping:

- Design the artwork: The first step in hot foil stamping is to create the artwork that will be stamped onto the surface. The artwork can be created using design software or by hand.

- Create the die: A die is a metal plate that is used to stamp the foil onto the surface. The die is created by etching the design onto a metal plate using a CNC machine or by hand.

- Set up the hot foil stamping machine: The machine consists of a heated plate or die, a foil roll, and a pressure mechanism. The foil roll is threaded through the machine and is held in place by tension.

- Adjust the temperature and pressure: The temperature and pressure settings of the machine must be adjusted based on the type of foil being used and the material being stamped.

- Load the foil onto the machine: The foil roll is loaded onto the machine and threaded through the rollers until it reaches the stamping area.

- Place the material to be stamped onto the machine: The material to be stamped, such as paper or leather, is placed onto the machine, in the position to be stamped.

- Stamp the material: The die is lowered onto the foil and the material with the appropriate amount of pressure, allowing the heat to transfer the foil onto the surface.

- Remove the material: Once the stamping is completed, the material is removed from the machine, and the excess foil is removed from the stamped area.

- Hot foil stamping can be used to create a range of effects, such as metallic or holographic finishes, and can be combined with other techniques like embossing to create unique designs.

Cost For Foil Stamping

The cost of foil stamping can vary depending on several factors, including the size of the area to be stamped, the type of foil used, the complexity of the design, and the quantity of the order. Generally, the larger the area to be stamped and the more complex the design, the higher the cost will be. The cost of the foil itself can also vary, depending on the type of foil used, such as metallic or holographic foil. In the printing industry, foil stamping is typically considered a premium finishing technique, and as such, it may be more expensive than other finishing techniques like embossing or UV coating. However, the cost of foil stamping can be offset by the value it adds to the final product, making it a popular choice for high-end packaging, invitations, and other printed materials. To get an accurate cost estimate for foil stamping, it's best to contact a professional printing company and provide them with the specifics of your project. They can provide a detailed quote based on the size, complexity, and other factors involved in the project.