The Checkmate series achieves the much-needed step of inspecting and segregating defect free print products from all printed material for the end user – typically for Pharma, Health Care, FMCG and Mobile phone industries. This helps avoid loss of brand value and legal implications that can arise out of defective cartons. This machine can identify defects like Color Variation, Mix-up of Cartons, defects on Metpet Cartons, Braille Defects, UV & Aqueous Coating Defects, Dead Insects / Stains and Printing Defects on Mono Cartons.

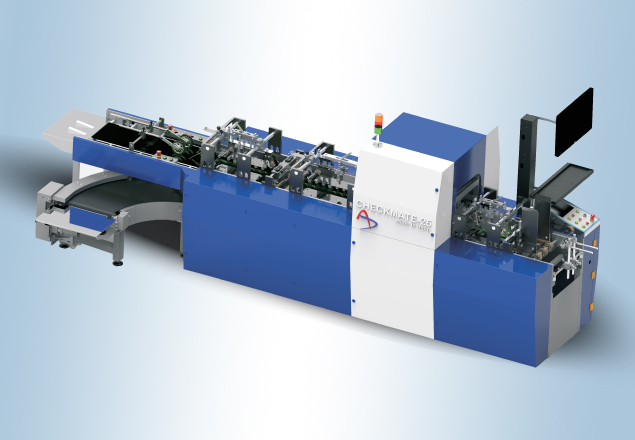

Autoprint is committed to bring modern cutting-edge technology to its customers. A result of this commitment is Autoprint CHECKMATE 25 a revolution in imaging technology for defect free print products to the end customer with 100% accuracy.

Autoprint is committed to bring modern cutting-edge technology to its customers. A result of this commitment is Autoprint CHECKMATE 50 a revolution in imaging technology for defect free print products to the end customer with 100% accuracy.