The Dextra Series can handle Die Cutting, Creasing, Embossing, Perforation, and Half-Cut on various substrates such as Maplitho, Sticker-Sheet, Art Board, and Duplex Board up to 600 gsm, depending on the model. Autoprint’s die punching machines and automatic die punching machines offer ideal solutions for industries such as Pharma, Health Care, and FMCG. These automatic die punching machines are particularly efficient for replacing manual die-cutting machines.

The Autoprint Dextra 67 die punching machine stands out as a versatile model that performs die punching, die cutting, creasing, embossing, braille, sticker half-cut, and envelope operations. The Autoprint Dextra 67 die punching machine is known for its reliability and efficiency as an automatic die cutting machine. The Autoprint Dextra 67 automatic punching machine is compact and designed to require minimal floor space, with its height optimized for ease of operation from the floor.

For added stability, the Autoprint Dextra 67 die punching or die cutting machine includes a Box type base frame. This automatic die punching machine is equipped with a centralized motor lubrication system for all areas and an oil bath for connecting links and shafts in the moving block assembly. The automatic die punching machine ensures long-lasting performance and reliability.

Autoprint prioritizes safety with various features. The Dextra 67 includes a safety switch for manual drive, robust steel side frames, a small platform for operator convenience, and ergonomically designed handles and knobs. The machine also features a high-speed centralized touch screen, an operational panel with PLC, and digital Input/Output modules.

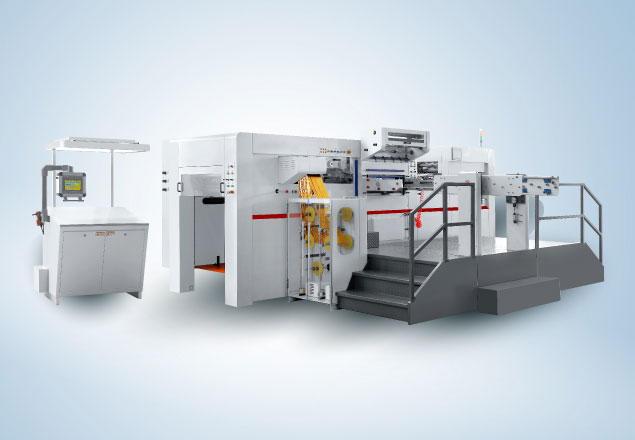

Autoprint is committed to bring modern cutting-edge technology to its customers. A result of this commitment is Autoprint Dextra 67- an Automatic Sheet-fed Flat Bed Die-Punching and Creasing Machine designed to handle even the most intricate and detailed designs.

Autoprint is committed to bringing modern cutting-edge technology to its customers. A result of this commitment is Autoprint Dextra 80 - an Automatic Sheet-fed Flat Bed Die-Punching Machine designed to handle even the most intricate and detailed designs.

Autoprint introduces the Repetto 105 an automatic die cutting machine. These machines are a perfect solution for Pharma, Health Care, FMCG and Corrugation industries.

Autoprint introduces the Repetto 105 an automatic die cutting machine. These machines are a perfect solution for Pharma, Health Care, FMCG and Corrugation industries.

In addition to the Dextra Series, Autoprint is a leading name among punching machine manufacturers and offers a range of advanced machines to meet various needs. Their lineup includes the manual die punching machine, which is perfect for operations that require a more hands-on approach. Furthermore, the Autoprint die cutting machine incorporates cutting-edge technology to provide precision and efficiency. For those seeking robust options, die cutting machine manufacturers like Autoprint also offer high-performance automatic hot foil stamping machines and hot foil stamping machines . These machines are designed to enhance the capabilities of any modern printing setup. The Autoprint Dextra machine and other models in the Dextra Series are well-regarded for their adaptability and high quality. Whether it’s the hot foil machine or a comprehensive die cut punching machine, Autoprint’s solutions cater to diverse operational requirements.

Autoprint also provides other models like the Autoprint Dextra 67 die cutting machine, which integrates advanced technology in automatic die cutting machines . Whether you need a manual die punching machine or an automatic die punching machine, Autoprint offers versatile options that cater to various operational requirements. The Autoprint Dextra Machine is renowned for its efficiency and adaptability, making it a great choice for modern printing punching machines.

For those interested in die punching manufacturers, die cutting and creasing machines , or automatic die cutter machines, Autoprint offers comprehensive solutions. The company also provides insights into the automatic die punching machine price and options from die cutting machine manufacturers.

Autoprint's expertise extends to offering a wide range of automatic punching machines designed to meet specific production needs. The auto punching machine models in our lineup provide seamless integration with existing printing machines, enhancing overall productivity and output quality. Our commitment to innovation ensures that whether you are looking for a robust die punch machine or advanced punching and cutting machine solutions, Autoprint delivers exceptional performance and reliability.

Furthermore, our die cutting and creasing machines are built to handle complex cutting and creasing tasks with precision. Autoprint stands out among automatic punching machine manufacturers for its dedication to providing cutting-edge technology and superior service. With a focus on both manual die punching machines and automatic printing machines, we offer a range of options tailored to meet the evolving needs of the printing industry. For those seeking the best in die cutting technology, Autoprint's advanced Dextra machine and other innovative models ensure optimal results for all your production requirements.

In addition, Autoprint continues to expand its offerings with the latest advancements in automatic die cutting machine technology, which includes the automatic hot foil stamping machine and other specialized equipment. Our printing punching machines are engineered to deliver superior performance across various applications, from high-speed production runs to intricate die cutting tasks. By investing in our die cutting and creasing machines, you are choosing a partner dedicated to enhancing your production capabilities with reliable, state-of-the-art machinery. Our extensive experience as a leading printing machine manufacturer ensures that we provide solutions that not only meet but exceed industry standards for quality and efficiency.