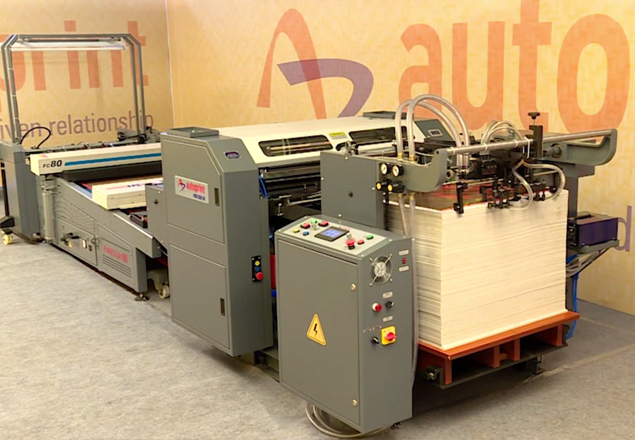

Autoprint Fine Coat 80 AX

Autoprint is always committed to bringing modern cutting-edge technology to its customers. Autoprint Fine Coat 80 AX, a Spot UV Coating Machine - offline sheetfed UV & Aqueous coating is one such revolutionary product from Autoprint. Autoprint Fine Coat 80 AX can perform full and spot (UV & Aqueous) coating on thin and thick papers at a speed of a maximum of 6000 sheets per hour. It is designed to meet the growing demand for a reliable and precision coater for large format printers and packaging units.

Autoprint Fine Coat 80 AX is an offline sheetfed Flexo Rotary Automatic UV and Aqueous Coater with UV and IR Dryer. It can perform Full or Flood coating, Spot coating, and Spot-not window coating of both UV-based and water-based (Aqueous) coatings.

View Brochure

It is equipped with 3 roller coating systems including a Chrome plated Anilox Roller and a doctor blade similar to a chamber doctor for better control of UV Varnish solution. It works on the letterpress dry offset principle with 2 cylinder system. The first cylinder is a plate cum blanket cylinder. We can use a blanket for doing full or flood coating, whereas Flexo or photopolymer plate is used for doing spot coating. We can achieve spot-not window coating by using stripped blankets wherever coating is not required. Spot not window coating is mainly used by pharma carton manufacturers to avoid coating on coding and pasting areas.

It is a brand new dedicated Coater with specially designed grippers and stainless steel coater unit and other parts to withstand the highly corrosive UV Varnish solution. Hence it is far better and advantageous than the used or converted coater in the long run. Why do we have to take a big risk on a converted coater when you are getting a brand new Spot UV Coating machine along with a dryer combined warranty with a marginal difference in cost? The Dryer unit also carries a One-year spare warranty and 1000 hrs replacement warranty for the UV and IR Lamps. The Lamps and reflectors are of high-quality standards imported from Germany. Autoprint has installed more than 280 machines of Fine Coat 80 in all leading pharma, and packaging companies all over India and abroad as of March 2018.

Our Spot UV Coating Machine can handle a minimum of 60 gsm chromo art mirror coated labels and paper up to 450 gsm board of size up to 22”x32”. The maximum speed is 6000 sheets per hour. It is ideal for large packaging printers as well as for starting Job work Units for UV Coating, Aqueous Coating, Spot Coating, Post Press process Jobs in a suitable location for serving clusters of printers. It is an ideal replacement upgrade solution for conventional manual feed or auto-feed roller coater and your old used dryer.

Apart from packaging, UV coating is also now popular among Publishing houses, where it is slowly replaced with UV-coated Book Cover pages instead of lamination Since lamination is a slow process that cannot match with the products made in offset presses. The creasing issues of book cover pages are also eliminated by using creasable varnishes and by the use of proper creasing tools in the perfect binding unit.

Features at a Glance

- Stream Feeder System

- Pull Type Side Lay On Both Sides

- Motorized Pile Up/Down Mechanism

- 3 Roller Anilox Coating System

- PLC Touch Screen Panel

- Electro Mechanical Double Sheet Detector

- No Sheet Detector

- Swing Arm Gripper

- Cylinder System for Flood & Spot Coating

- Separate Geared Motor For The Coating Unit

- Pneumatic Operation

- Peristaltic Varnish Pump

- Main Motor With Brake For Instantaneous Stopping Of Machine For Operator Safety

- Automatic Lubrication Unit

- Connectable to UV/IR Dryer Unit

- *Coating Thickness: 3 - 8 gsm Depending Upon Combination Of Anilox And Form Roller Of Different LPI And Hardness

Features

- Ultra Sonic Double Sheet Detector

- Changeable Anilox Roller With 300 LPI Standard on Machine

- CE Compliant Machine

- Anilox Roller Assembly

- Pre-piling Facility for Feeder

- Hogh Pile Delivery Stacker

- Antistatic Device (Optional)

Standard supply of UV/IR Dryer unit comprising of the following:

- 12 ft Vacuum Hold-down, Teflon Coated Fiber Belt Conveyor.

- One IR Module comprising 2 IR Lamps of 3 Kw each.

- One UV Module comprising One UV Lamp of 300 Watts per inch power.

- Automatic Receding Pile with Delivery Stacker

Technical Specifications

| Model | Autoprint Fine Coat 80 AX (UV & Aqueous Coating) | Model | Autoprint Fine Coat 80 AX (UV & Aqueous Coating) |

|---|---|---|---|

| Maximum Paper Size | 560 x 812 mm (22" x 32") | Minimum Paper Size | 250 x 300 mm (10" x 12") |

| Maximum Coating Size | 550 x 800 mm | Paper Thickness | 60-450 gsm |

| Max. Coating Speed | 6000 sph | Blanket Size for Flood Coating | 640 x 822 x 1.70 mm (4 ply) |

| Polymer Plate Thickness (For Spot Coating) | 1.70 x 0.3 mm x 0.1 mm (for double side tape) | Coating Thickness | 3-8 gsm* |

| Gripper Margin on Plate | 35 mm | Gripper Margin on Paper | 10 mm |

| Gripper Bite | 5 mm | Circumferential Image Micro Adjustment | 30 mm offline |

| Registration Accuracy | ± 0.5 mm | Side Lay Fine Adjustment | ± 1.5 mm |

| Delivery System | Chain Delivery | Power Supply | 3 Phase 415 V, 50 Hz |

| Coating Power Consumption | 4.5 Kw (6 Hp) | Main Drive Motor | 1.5 Kw (2 Hp) |

| Compressor Motor | 1.5 Kw (2 Hp) | Pile Up / Down Motor | 0.75 Kw (1 Hp) |

| Lubrication Pump | 0.18 Kw (0.25 Hp) | Varnish Motor | 0.375 Kw (0.5 Hp) |

| Varnish Pump | 230V, 50Hz, Single Phase AC | Dryer Power Consumption | 12.5 Kw (17 Hp) (for 12 Feet Standard Dryer) |

| Total Power Consumption | 17 Kw (23 Hp) | Dimensions (L x W x H) | 6750 x 1800 x 1680 mm (with 12 Feet Standard Dryer) |